-

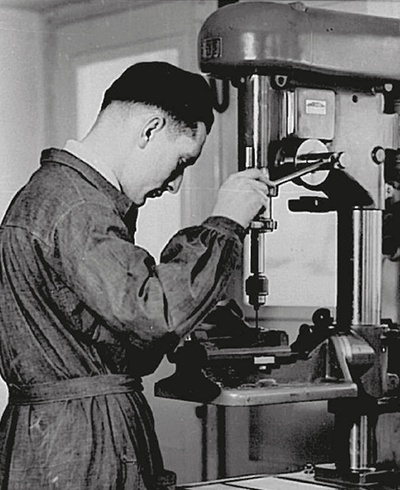

Foundation of HEINZ KAISER AG.

The 23-year-old Heinz Kaiser decides to set up his own business. His vision: the development of high-quality tools. His goals: The modern tools, which are produced in his workshop, should meet high standards. With his Schaublin 102 TO lathe, he moves into his first own workshop in Rümlang, Switzerland.

-

First turning tool

First precision boring tools that achieve bores of high surface quality and great accuracy. Guaranteed infeed accuracy of 0.003 mm.

-

Piccolo facing head

The Piccolo finds its application on a wide variety of machines thanks to its unique accuracy and handiness and is described as a small universal wonder.

-

New building Rümlang

The dream of new manufacturing premises becomes a reality for Heinz Kaiser.

-

First modular tool system

Quick-change shank with simple, very accurate, hand-operated clamping device for holding tool heads and boring bars.

-

Foundation of BIG DAISHOWA Seiki

In Osaka, Japan, the BIG DAISHOWA company opens a production facility for tool holders.

-

Invention of the CK cut-off point

The CK parting point is based on a cylindrical plug-in connection with radial clamping, which enables simplified merging of the precision turning tool and the basic holder.

-

Licence agreement with BIG DAISHOWA

Heinz Kaiser signs an agreement with the Japanese company BIG DAISHOWA SEIKI for the licensing of the KAISER tool range.

-

Foundation of KTP/KAISER Precision Tooling in the USA

The subsidiary KPT/Kaiser Precision Tooling Inc. is founded in Chicago.

-

The stiffest double contact system in the world

Invention of the BIG-PLUS® spindle system.

-

BIG KAISER Precison Tooling INC.

The strategic connection with BIG DAISHOWA leads to the new name BIG KAISER at KPT.

-

Foundation of BIG KAISER Germany

To expand the European market, BIG KAISER GmbH is founded in Germany.

-

Digital Age

With the first digital fine boring tool EWD, BIG KAISER ventures the first step into the digital age.

-

KAISER becomes BIG KAISER

The family business KAISER becomes part of the Japanese tool manufacturer and long-term partner BIG DAISHOWA.

-

E for Evolution

With the development of the EWE fine boring head, BIG KAISER takes the step into Industry 4.0 and receives the Prodex Award for it.

-

Industry 4.0

The second step towards Industry 4.0 with the fully automatic fine boring head EWA.

-

Smallest digital fine boring head in the world

The world's smallest fine boring head finally goes digital thanks to the EWE\'s wireless technology.